Hot Disperser System

Shells Machinery Has successfully designed & Manufacturing different Types of conveyor i.e Slat Conveyor, Belt Conveyor , Screw Conveyor. Conveyor are suitable for conveying pulp , waste paper , coal , cement, starch etc.

Brochure

Download our document to see specific data of the service and how we work.

Let’s Start Work

Together

Please feel free to contact us. We will get back to you with 1-2 business days. Or just call us now.

How can we help?

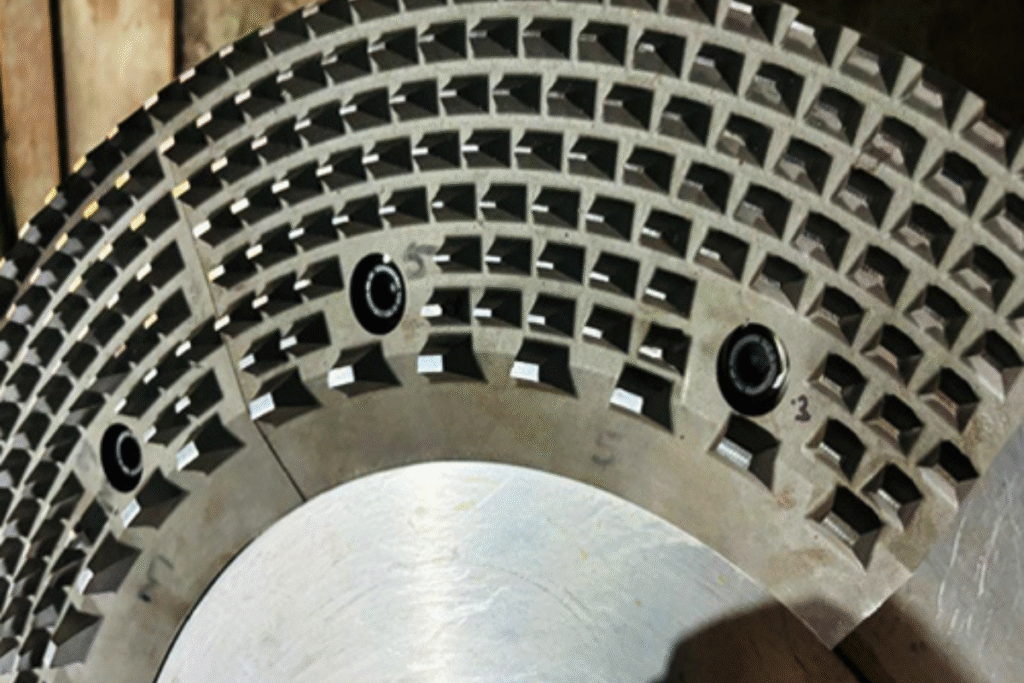

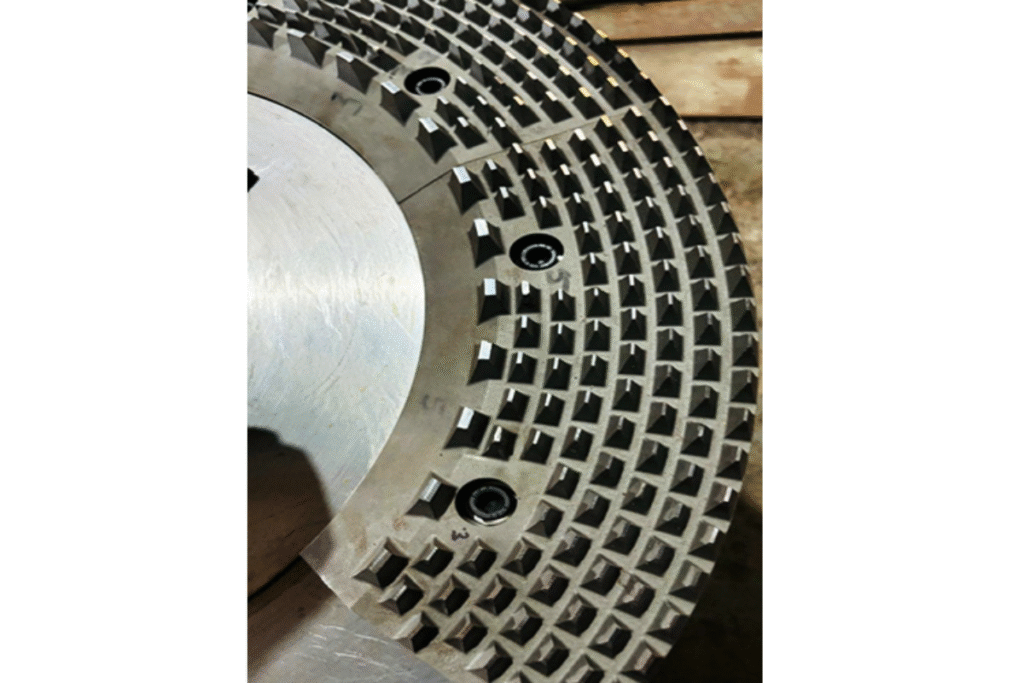

DISPERSER DISC

Our Solutions & Benefits

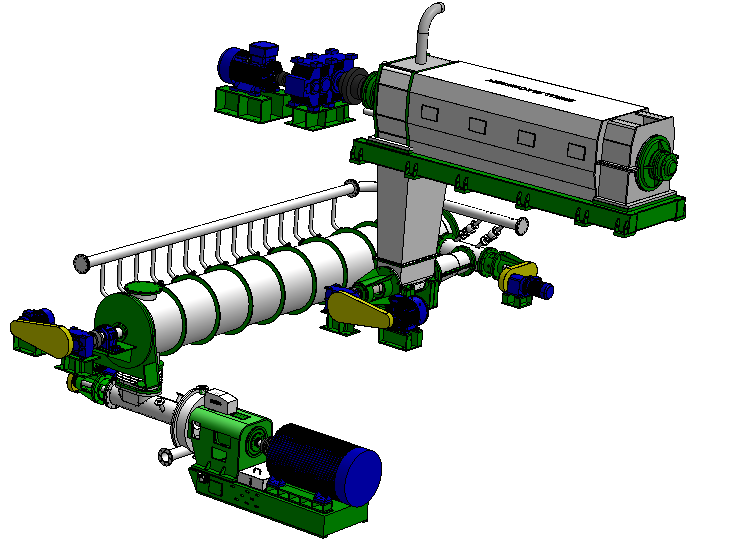

Shells Machinery offers high-efficiency Hot Disperser Systems engineered for uniform fiber treatment. Our systems include a robust disperser unit, heating system, and feeding screw, all designed for continuous operation, consistent dispersion, and minimal fiber damage.

- Improved Pulp Brightness: Effectively disperses ink and impurities for cleaner pulp.

- Enhanced Sheet Quality: Reduces spots, dirt specks, and fiber clumps in the final product.

- Energy-Efficient Design: Optimized heating and mixing for lower power consumption.

- Durable Build: Heavy-duty components ensure long-term, reliable performance.

- Compact & Integrated: Space-saving design with easy installation into existing lines.

What is Included

Shells Machinery was established in 1979 by Mr. Keshubhai Panchal, a mechanical engineering expert with a vision to build quality machinery for the pulp and paper industry.

We are one of the leading manufacturers and suppliers of pulp and paper machinery, specializing in equipment used for Kraft, Tissue, Writing, Printing, and Duplex Board production — especially in stock preparation.

With over four decades of experience, a commitment to quality, and long-term client relationships — including a 30+ year partnership with Ruby Macons Ltd. — we combine trust with innovation in every machine we build.

Absolutely. We design and manufacture tailor-made solutions based on your specific plant layout, production needs, and budget.

We specialize in machinery for Kraft, Tissue, Writing, Printing, and Duplex Board production, with a strong focus on stock preparation systems.