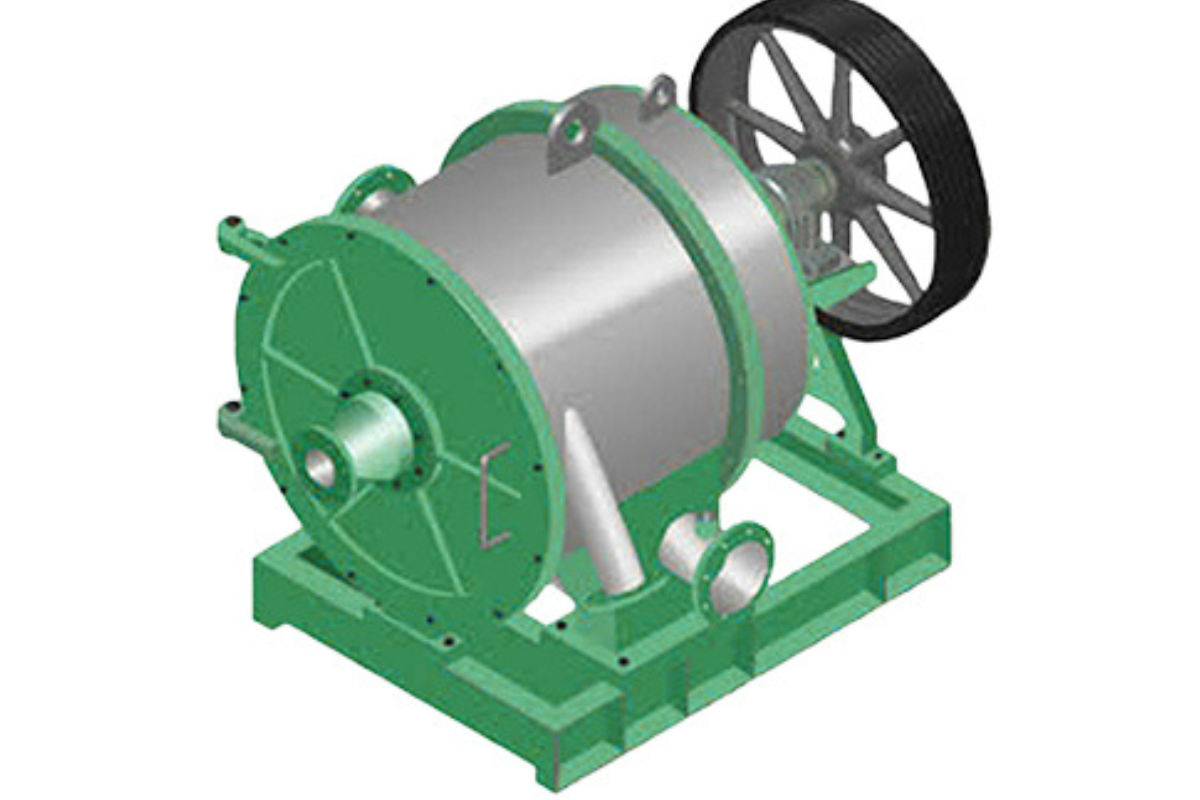

(COARSE SCREEN) TURBO SEPARATOR

Shells Machinery Has successfully designed & Manufacturing Turbo Separator. Turbo Separator is a disc screen specially deigned for coarse screening of primarily for pulp strainer with a high trash and flake consent like recycled paper. It is used for removal of both light & heavy rejects separately.

Brochure

Download our document to see specific data of the service and how we work.

Let’s Start Work

Together

Please feel free to contact us. We will get back to you with 1-2 business days. Or just call us now.

How can we help?

The Turbo Separator, also known as a Coarse Screen, is used in the initial stages of stock preparation to efficiently remove large contaminants such as plastics, string, rags, and other heavy rejects from recycled or virgin pulp.

Application & Salient Features

- Most suitable in screening of pulp slurries with high trash and flake content

- Can be used as a secondary screen with a cylindrical screen in the first stage

- Online contaminants removal of both light and heavy rejects separately

| Model | 1 | 2 | 3 | 4 | 5 | 6 |

|---|---|---|---|---|---|---|

| 300 | 400 | 500 | 600 | 800 | 1000 |

Working Principle – The Pulp stock is feed to inlet chamber through a tangential inlet. Inlet chamber is also having heavy reject outlet and light reject outlet at the center of the chamber door. Between accept chamber and inlet chamber there is a screen with a rotor having several curved blades.

Our Solutions & Benefits

Shells Machinery manufactures robust Turbo Separators with specially designed rotors that generate powerful turbulence, ensuring continuous separation without clogging. Our systems are engineered for high capacity, low fiber loss, and long-term durability — making them ideal for demanding pulp processing environments.

Efficient Contaminant Separation: Removes coarse impurities early, protecting downstream equipment.

Low Fiber Loss: Retains valuable fibers while eliminating rejects.

Non-Clogging Design: Rotor-driven turbulence prevents screen plugging and increases uptime.

High Throughput: Designed for continuous, high-volume processing.

Heavy-Duty Build: Corrosion and wear-resistant construction ensures long service life.

What is Included

Shells Machinery was established in 1979 by Mr. Keshubhai Panchal, a mechanical engineering expert with a vision to build quality machinery for the pulp and paper industry.

We are one of the leading manufacturers and suppliers of pulp and paper machinery, specializing in equipment used for Kraft, Tissue, Writing, Printing, and Duplex Board production — especially in stock preparation.

With over four decades of experience, a commitment to quality, and long-term client relationships — including a 30+ year partnership with Ruby Macons Ltd. — we combine trust with innovation in every machine we build.

Absolutely. We design and manufacture tailor-made solutions based on your specific plant layout, production needs, and budget.

We specialize in machinery for Kraft, Tissue, Writing, Printing, and Duplex Board production, with a strong focus on stock preparation systems.